Example of applications:

- Green Technology and Innovation for project management, e.g.

- Rebar manufactured in electric furnaces instead of blast furnaces to reduce the carbon emissions during manufacturing.

- Digitisation of project management, e.g.

- Online system for document circulation, to reduce paper use;

- Digital platform for performance tracking, project benchmarking, material submission and method statement submission.

Low Cost applications:

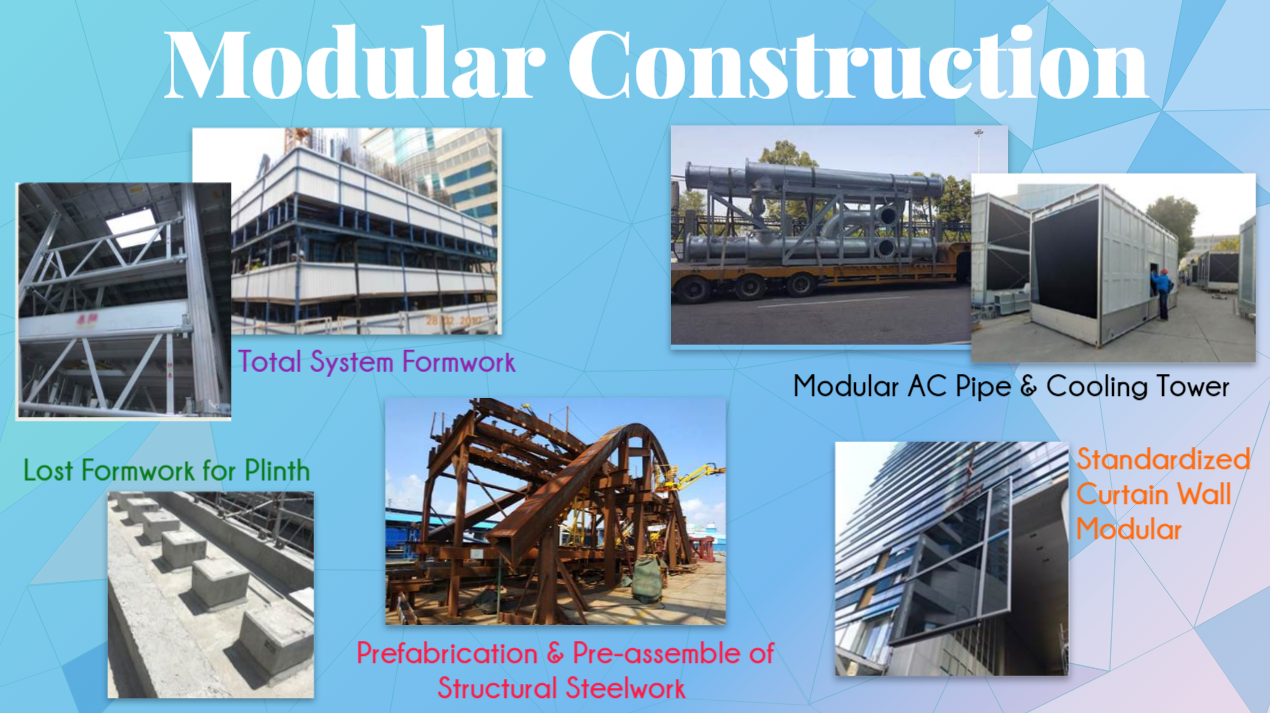

- Application of Engineering Design/Alternative Construction Method, e.g.

- Replacement of timber with steel for lift shafts;

- Replacement of timber with aluminum for formworks;

- Use of alternative designs to save materials;

- Use of alternative designs to re-use metal modules for horizontal supports, and use bolt and nut installation instead of welding;

- Application of engineering design to reduce the amount of excavated materials;

- Application of engineering design to reduce the time for rock breaking;

- Application of engineering design of method statement to use micro (2m) TBM to replace manual digging;

- Large-scale bored piles instead of pre-bored minisockets, to save time;

- Small TBM to replace open-cut to minimise ground air pollution and save time;

- Trenchless technology to replace open-cut to minimise ground air pollution and save time;

- Pre-cast concrete slabs for tunnels (ventilation ducts) to save time and minimise metal rebar consumption;

- Alternative structural supports to reduce the excavation to reduce noise, C&D waste and CO2 emissions

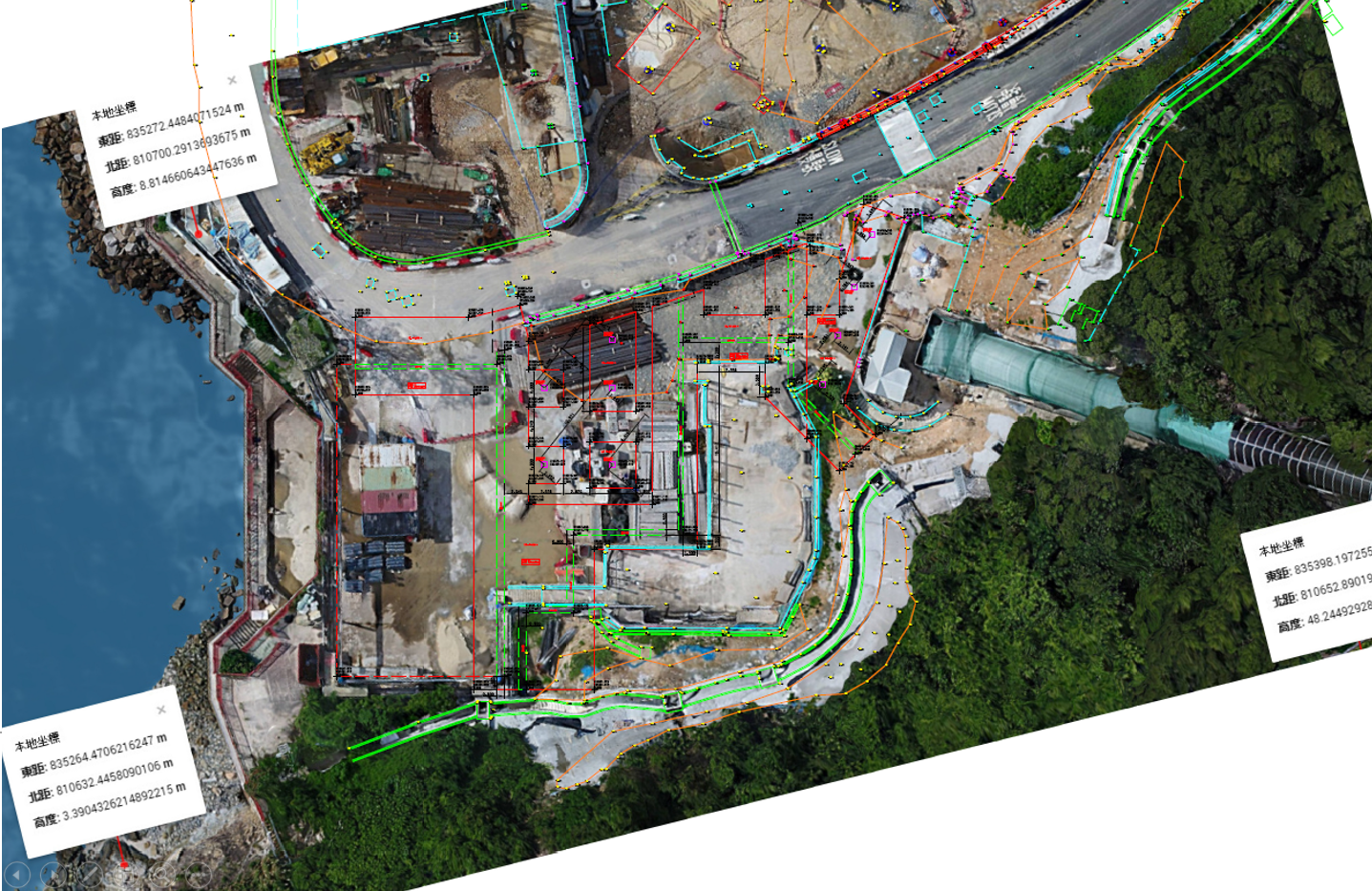

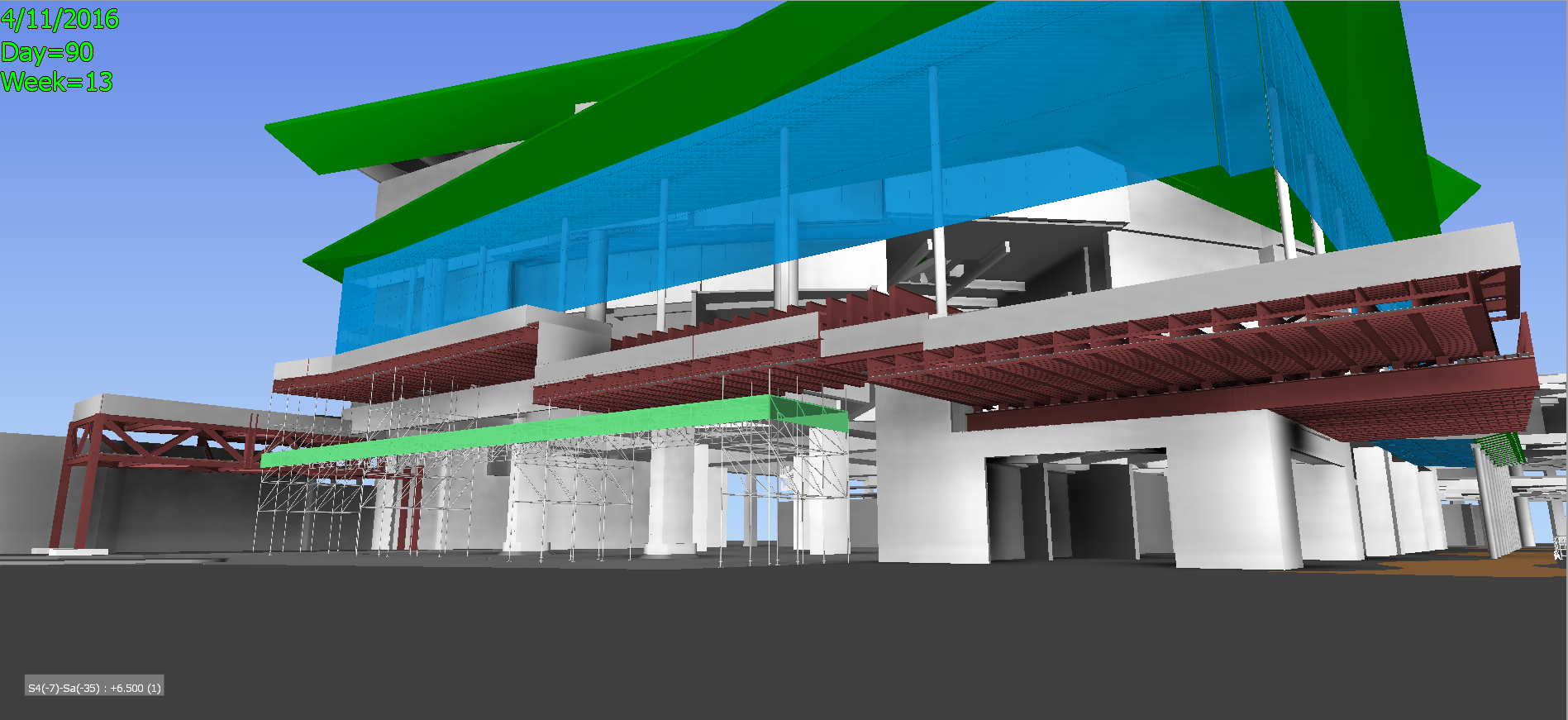

- Application of BIM, e.g. for

- permanent works, incl. stages of design, construction and as-fit works;

- site work planning;

- temporary works;

- later MEP stage to avoid material clashing;

- cash control in design and installation process.

Sustainability KPI:

- Percentage reduction in CO2 emissions (kg) from use of alternative construction methods, per project (%)

- Percentage reduction in materials used, by engineering design (%)

- Percentage of time gained in construction process, by engineering design (%)

- Percentage use of steel rebar manufactured in electric furnaces instead of blast furnaces (%)